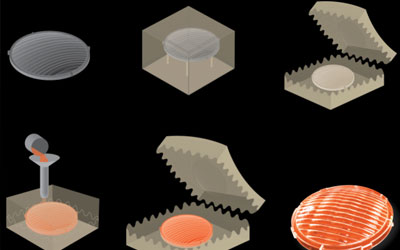

Express Vacuum Casting

Express Vacuum Casting is the perfect solution for one offs and smaller batches in silicone or rubber parts with complex geometries and low volume production runs or multiple prototypes really fast to save you time and a lot of money for a production injection mold tooling.

Express Vacuum Casting is an industry standard technique used for the production of small series of functional plastic parts by using two-component polyurethanes and silicone molds for fast production of high-quality prototypes or end products. By using our Express Vacuum Casting services, we can quickly inspect and verify your design as well as help to identify any potential product design issues to save you time, energy and money.

Casting material:

Similar ABS, PC, POM, PP; Rubber, silicone etc, Max Size:

2500x1000x1000mm, Tolerance: 100mm/±0.20mm

Mold shot times: 10-12, Controlled thickness: less 3.00mm

Express Vacuum casting allows for parts to be self-coloured and the urethane casting process assisted by a vacuum which ensures a high degree of conformity and tight tolerances. The vacuum casting parts can be produced in a broad range of surface finishes/coatings and colours or transparencies.